The world of textiles is undergoing a fragrant revolution with the advent of scent-infused fabrics. At the heart of this innovation lies microencapsulation technology, a groundbreaking method that enables fabrics to retain and release fragrances over extended periods. This marriage of science and sensory pleasure is redefining how we experience textiles in our daily lives.

Microencapsulation works by trapping tiny droplets of fragrance oils within microscopic polymer shells. These capsules, measuring mere microns in diameter, become embedded in fabric fibers during the manufacturing process. The magic happens through controlled release mechanisms - friction, body heat, or gradual breakdown causes the capsules to rupture, releasing their aromatic payload. This creates a sustained fragrance experience unlike any temporary spray or wash-in solution.

The technology's applications span multiple industries, from high-end fashion to functional sportswear. Luxury brands are incorporating scented linings in coats that release subtle perfume when moved, while athletic apparel companies develop workout gear that masks body odor with fresh citrus or marine notes. Home textiles represent another growing market, with scented curtains, bedding, and upholstery creating ambient fragrance without candles or diffusers.

What sets microencapsulation apart is its remarkable longevity. Traditional fabric sprays might last through a single wear, but encapsulated fragrances can survive up to 30 washes before needing renewal. This durability stems from the protective shell surrounding each fragrance molecule, shielding it from premature evaporation or degradation. The capsules essentially create a reservoir system within the fabric's structure.

Environmental considerations have driven significant advancements in microcapsule composition. Early versions relied on synthetic polymers, but contemporary iterations increasingly use biodegradable materials like chitosan or modified cellulose. Fragrance oils themselves are evolving toward plant-based, allergen-free formulations to accommodate sensitive users. These developments address growing consumer demand for sustainable yet luxurious textile innovations.

The sensory impact of scented fabrics extends beyond mere aesthetics. Psychological studies suggest certain fragrances can influence mood and perception - lavender for relaxation, citrus for energy, or vanilla for comfort. Hotels now experiment with linen infused with calming chamomile, while corporate offices test curtain fabrics emitting focus-enhancing rosemary. This neuroaesthetic approach transforms passive textiles into active well-being tools.

Manufacturing scented fabrics presents unique technical challenges. Capsule size must be precisely calibrated - too large and they compromise fabric drape, too small and they lose fragrance capacity. Distribution uniformity affects scent consistency, while bonding methods determine wash resistance. Leading textile chemists have developed proprietary application techniques, some involving specialized curing processes that permanently fix capsules between fiber molecules.

Consumer adoption patterns reveal fascinating cultural variations. European markets initially embraced scented home textiles, while Asian consumers drove demand for personal apparel applications. North American adoption has been particularly strong in performance sectors like yoga wear and outdoor gear. This global patchwork reflects differing cultural relationships with personal scent and textile expectations.

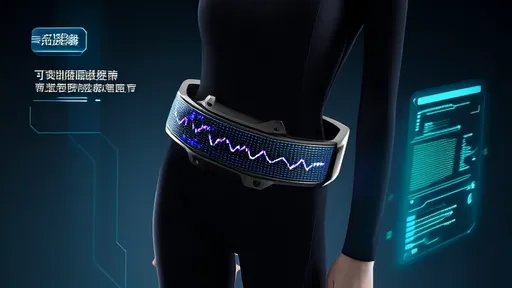

The future of fragrance textiles points toward smarter, more responsive systems. Phase-change materials may enable scent release triggered by specific temperatures or humidity levels. Some prototypes incorporate multiple fragrance types that activate at different times, creating evolving scent profiles throughout the day. The most ambitious concepts involve biosensors that adjust fragrance based on the wearer's stress levels or environmental pollutants.

As this technology matures, it raises intriguing questions about the evolving relationship between fashion and olfaction. Where traditional perfumery creates scent experiences separate from clothing, microencapsulation merges these elements into a unified sensory medium. This convergence may ultimately redefine how we think about personal fragrance and textile personalization in the coming decades.

Industry analysts project the scented textile market to grow exponentially as production costs decrease and consumer awareness increases. What began as a novelty in premium segments is trickling down to mass-market applications, from scented socks to aromatic car seat covers. The technology's versatility ensures its adaptation across price points and product categories.

Critically, the success of scented fabrics hinges on subtlety. Overpowering or poorly chosen fragrances can alienate rather than attract users. Successful implementations use carefully calibrated scent levels that create intimacy rather than announcement - detectable at conversational distances but not room-filling. This nuanced approach reflects an understanding of scent as personal rather than public expression.

The intersection of textile engineering and perfumery represents one of fashion technology's most intriguing frontiers. As microencapsulation methods grow more sophisticated, we may see fabrics that not only smell pleasant but actively contribute to hygiene, mood regulation, and even aromatherapeutic benefits. This innovation transforms clothing from mere covering to multi-sensory experience, redefining our most intimate interface with technology.

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025